Gas Atomizing

Possible to manufacture the high purity powder.

Gas Atomizing

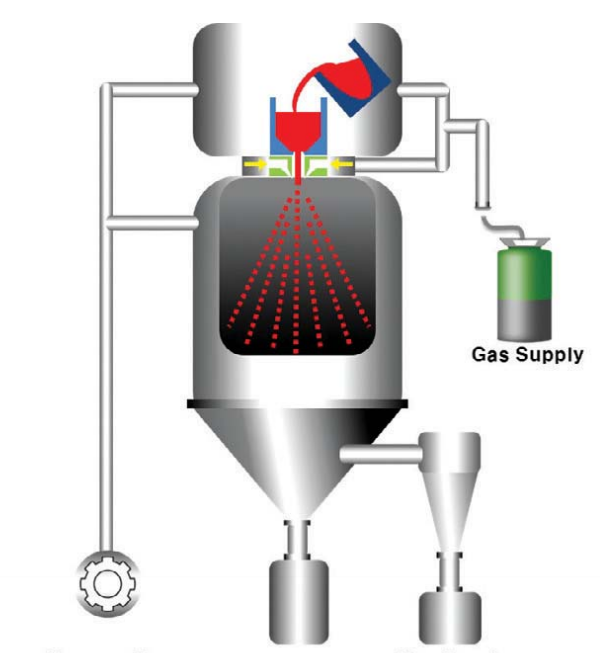

Gas Atomizing Process

Gas Atomizing Process

Vacuum Pump

Coarse Powder

Fine Powder

Parent Material Melting

Vacuum

Furnace Heating

Gas Substitution

Furnace Heating

Gas Substitution

Gas Atomizing

Furnace Tilting / Swelling

Gas Injection

Gas Injection

Powder Formation

Cooling

Powder Collecting

Powder Distribution

Powder Collecting

Powder Distribution

Gas Atomized Powder Properties

- Manufacture the powder Which is under Size 500 micron

- Possible to manufacture the high purity powder

- Uniform particle size distribution / Excellent filling properties

- Possible to Manufacture the spherical shape powder

- Increase the production capacity

←

Gas Atomizing

Standard for evaluation of metal powder properties

- Particle size & distribution of powder

- Shape

- Flowability / Liquidity

- Tap Density

- Composition(High Purity)

Process Condition Optimization

- Vacuum

- Gas Pressure

- Melt Furnace Temp.

- Viscosity of Melted

- Metal Nozzle Structure

Gas Atomization Characteristic

The spray method can be applied to any soluble metal

It can be manufactured form unit metal powders such as Fe, Ni, Cu, Al, Zn, Sn, Ti to alloy powders such as Inconel, Stainless Steel, High Speed Steel, Stellite.

It can be freely adjusted the apparent density, particle size, distribution and shape of the powder by adjusting the method of differentiating molten metal & conditions.

Customer Service

053-857-3541