HIP

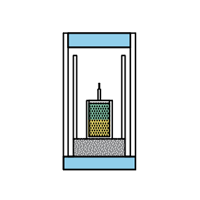

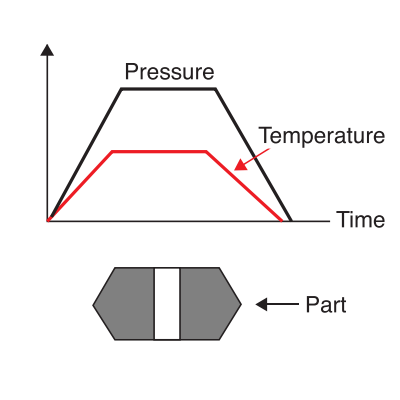

H.I.P system make to eliminate the pore in the materials and improve the property of materials.

Application of H.I.P

Application of H.I.P

■ Superalloy

※Creep rupture properties of Ni-Base Superalloy

| Alloy | H.I.P | Test Conditions | Life(ks) | Elongation(%) | R/A(%) | |

|---|---|---|---|---|---|---|

| Temperature(K) | Stress(MPa) | |||||

| Inconel 738 | × | 1253 | 152 | 68.4 | 11.8 | 20 |

| ○ | 1253 | 152 | 189 | 20.5 | 20.6 | |

| Rene 77 | × | 1253 | 152 | 183.6 | 19.4 | 37 |

| ○ | 1253 | 152 | 244.8 | 22 | 55 | |

| Inconel 792 | × | 1143 | 310 | 630 | 9.2 | 6.5 |

| ○ | 1143 | 310 | 1018.8 | 12.1 | 22 | |

| Rene 80 | × | 1143 | 310 | 149.6 | 2.5 | 2.5 |

| ○ | 1143 | 310 | 507.6 | 11.5 | 17 | |

■ Casting

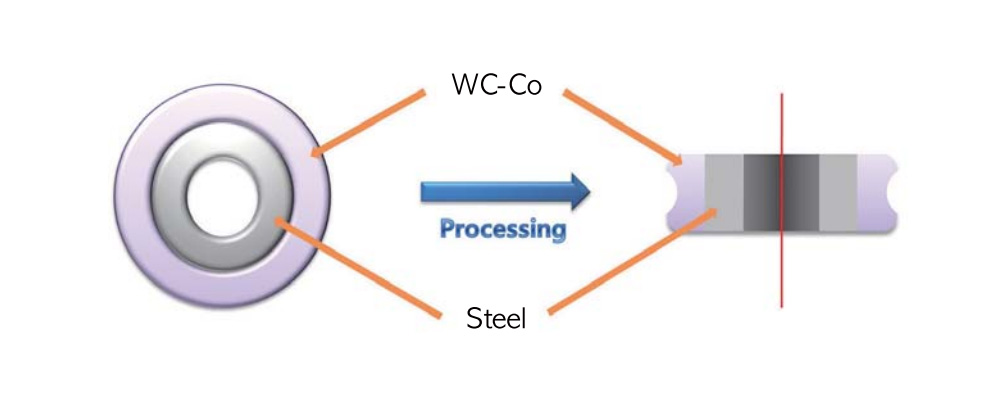

■ WC-Co, Ceramic

■ P/M HSS

■ 3D Printing

Hipping fo AM parts

As built

After HIP

Ref: Porosity regrowth during heat treatment of hot isostatically pressed additively manufactured titanium components, S.Tammas-Williams et al, Scripta Materialia 122(2016) 72-76

■ HIP only eliminates intemal, isolated defects

- Surface defects are not eliminated

- Porosity acts as stress concentrations and crack initiation points

- Porosity acts as stress concentrations and crack initiation points

■ HIP gives~100% relative density

- Improved ductility and fracture toughness

- Much improved fatigue properties

- Lower scattering in properties

- Better machined surfaces

- Much improved fatigue properties

- Lower scattering in properties

- Better machined surfaces

■ The Use of Hipped Materials

| Hipped Material | Application |

| Al O | Battery components |

| Al alloys | Aerospace castings, Turbo-impellers |

| Co-based Superalloy | Medical implants |

| Encapsulated powder | Turbine discs, Claddings, High speed & Tool steel |

| Mg alloys | Aircraft components |

| Magnetic materials(Ferrites) | Electromagnets and Permanent magnets |

| Ni-Al Bronze | Naval castings |

| Plasma-sprayed coatings | Wear and Corrosion-resistant facings |

| Si N | High-temperature components |

| Steels | High-strength parts(Aerospace and automotive) |

| Ti alloys | Aerospace castings |

| WC hardmeta | Cutting tools and Wear parts |

■ The Composite Technology by Canning H.I.P

It is possible for the bind technology for other materials or same materials by Canning H.I.P

- It’s easy to manufacture the items which can be made difficult with welding or brazing method

- Bonding of dissimilar material such as metal, ceramic

- It can be applied for various fields.(ex. target, cooling channel, bonding-pipe)

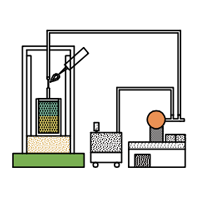

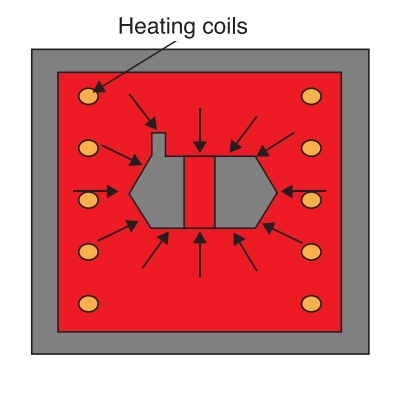

■ Canning HIP Process

Preparation

→

↓

Welding

→

↓

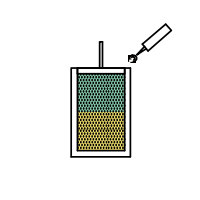

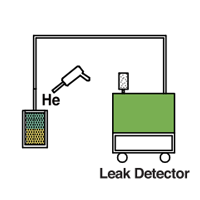

Leak Test

→

↓

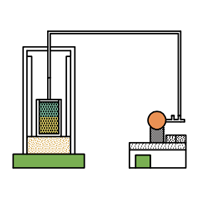

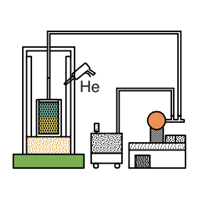

Degassing

Leak Test

→

↓

Sealing

→

↓

Bubble Test

→

↓

HIP

Finish

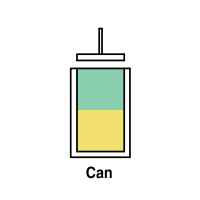

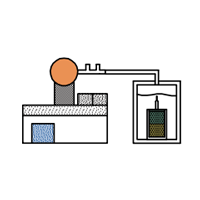

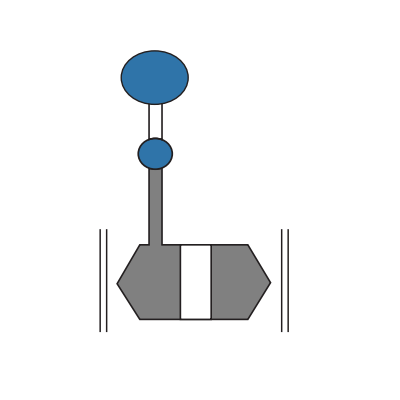

■ Powder Canning H.I.P

(a)

Fill can

Fill can

(b)

Vacuum bakeout

Vacuum bakeout

(c)

Hot isostatic press

Hot isostatic press

(d)

Remove can

Remove can

- It's possible to make the alloy which has hard conditions.

- Manufacture the P/M HSS

- Manufacture the carbon-carbon composite

- Manufacture the sputtering target for semiconductors

- It can be applied for various fields. (ex. roller, knife, wear-resistance products)

Customer Service

053-857-3541